Case Study

Production Planning in Manufacturing

Introduction

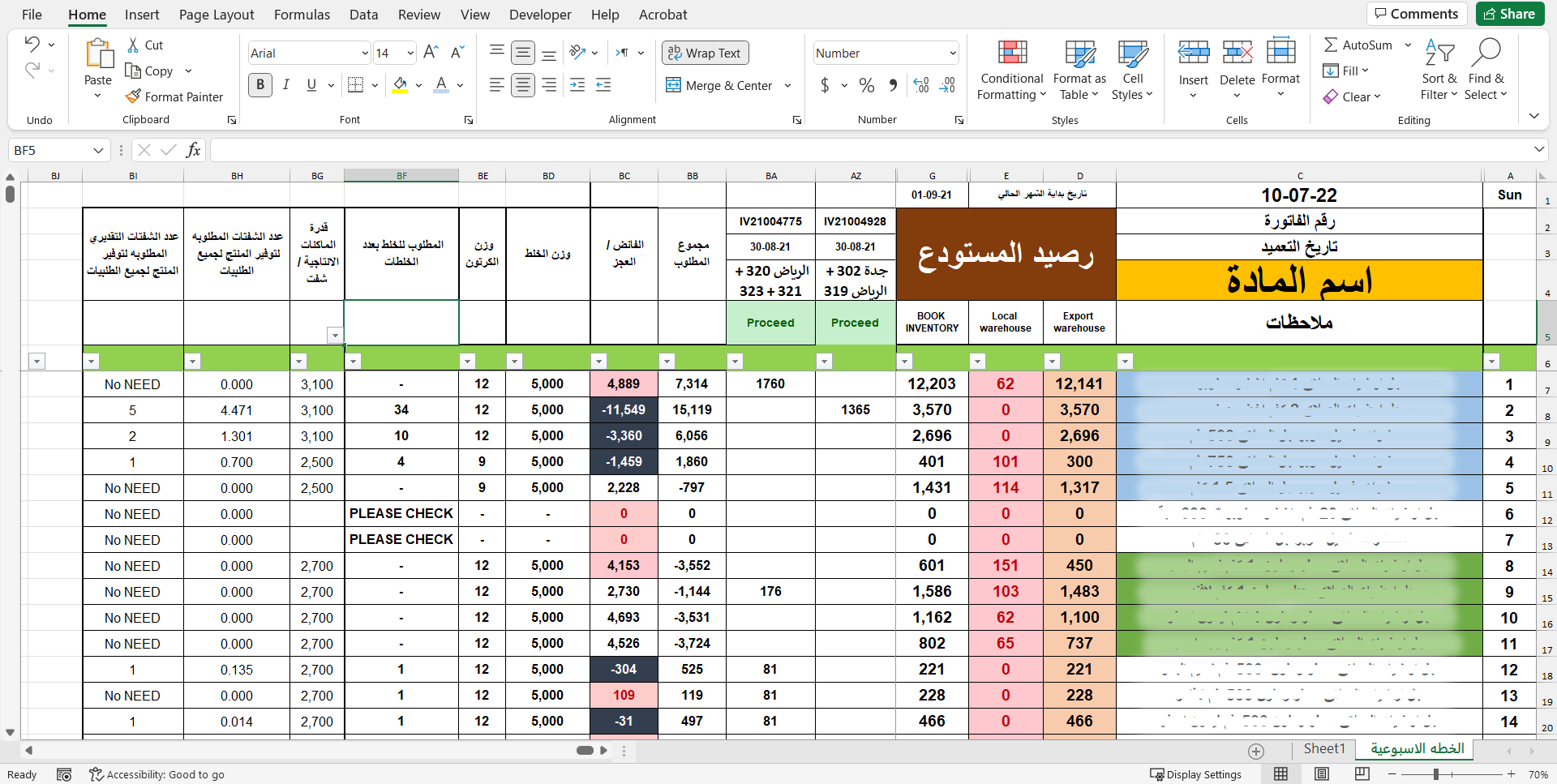

A factory used excel sheets to plan their weekly production. Although their ERP system had all the needed data, but it was difficult to combine all this data into the required format and calculations, so the team decided to use excel to feed and combine the data. These were the steps:

-

Warehouse team feeds the stock of each item on daily basis.

-

Sales team feeds orders Qty (as columns) next to each item.

-

Production team uses formulas specific to each item to calculate how many batches needed to fulfil the orders.

The Problem

-

Enormous effort to feed Qty ordered against each item, considering thousands of items.

-

Latency in data feeding which will result in inefficiency in the production process.

-

Human mistakes in data entry and formulas.

-

Crashes in the excel file due to the huge amount of data and multiple users.

-

Difficulty navigating through the sheet with hundreds of columns and rows.

The Solution

fornax solutions was able to:

-

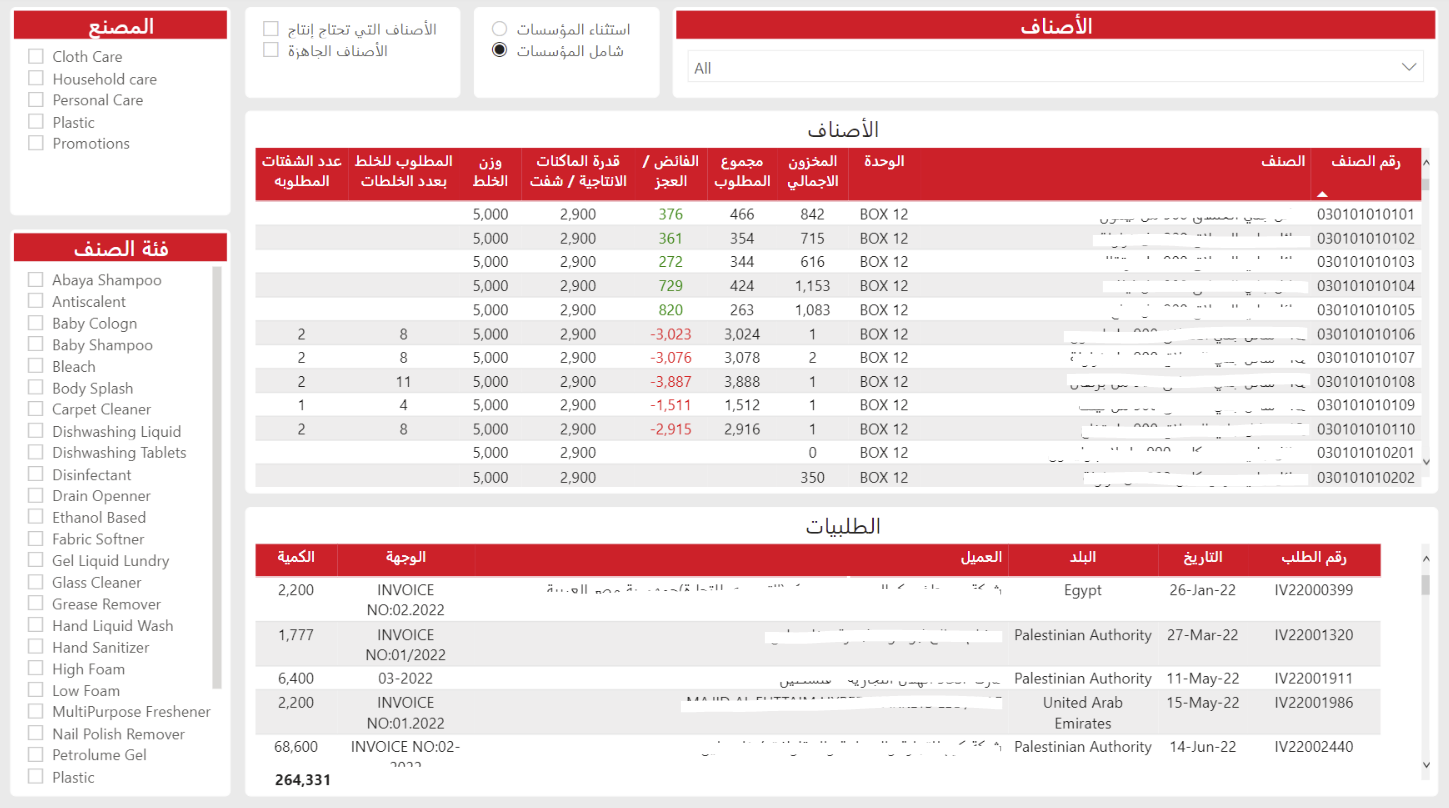

Model the data from the ERP system to suite the complex calculations and formatting.

-

Combine multiple departments data into one repository.

-

Develop a single, live, dynamic Dashboard that reads the information and present it in a user-friendly manner.

-

Added the possibility to check orders availability on the spot which was not possible earlier.

The Outcome

-

Saved the time and effort needed to feed information.

-

Live reporting which resulted in increased production efficiency.

-

No more mistakes in formulas and calculations.

-

Stable dynamic report (No downtime).

-

Simple, easy to navigating report (Few clicks to get any result).

40

%

Increase in Sales Team Efficiency

25

%

Increase in Production Team Efficiency

15

%

Increase in Warehouse Team Efficiency

Contact Us

Get in touch now and let us show you what we can do to improve your business!